2.5 - Fuel Pump Assemblies

Many fuel pump parts and assemblies are available on the market. Pumps, hangers, senders, complete assemblies and in-tank pump modules are the common replacement parts of the fuel delivery system.

Most pumps can be replaced separately but it is preferable to choose a complete assembly for the following reasons:

- When the fuel tank is removed

- Sealing surface

- Rust or burnt terminals

- Fuel tank damage

- Pump support bracket damage.

For all of these reasons, the cost of a pump assembly is much less than the risk of frustration!

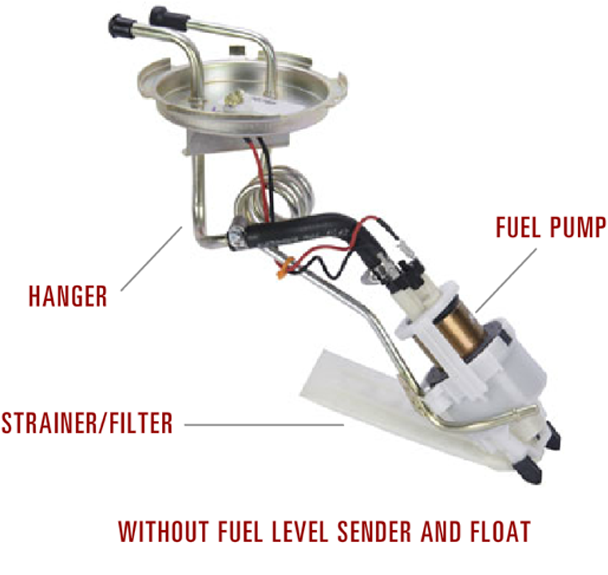

Hanger Assemblies

The hanger assembly is a unit with the fuel pump but it has no float. These models usually have a separate fuel level sender mounted on the tank.

This model is replaced if the fuel pump fails or damage is found on the electrical connector, if there is rust on the hanger unit, or if pump support is broken.

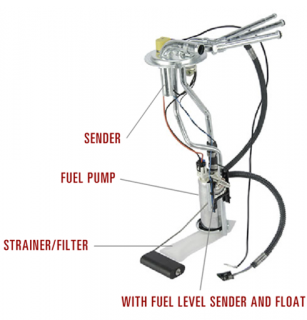

Sender Assemblies

The sender assembly comes complete with the hanger, pump and incorporates a fuel level sender. This model is replaced when the fuel pump fails or damage is found on the electrical connector, if there is rust on the unit, if the float level sensor is inaccurate or inoperative, or if the pump support is broken.

Fuel Module Assemblies

The fuel module assembly found on many models is a completely new concept where the fuel pump is integrated to a reservoir. The pump is not serviceable separately: the complete module assembly must be replaced when failure occurs. This concept keeps the pump immersed in fuel even when the tank is low. Some are complete with sender, float, pump and strainer. Few models need assembly.

Identifying General Motors

Some General Motors light trucks and vehicles have different fuel delivery systems.

To identify the appropriate unit, some will have a code tag: it is found on the wiring harness or on the fuel pump assembly.

Others will require use of a RPO code (Regular Production Option) found on the label: the label may be located in the luggage compartment, glove box or under the hood.

This information is necessary to obtain correct assembly.

Fuel Level Sensor

The sending unit is a variable resistor that is controlled by a float and float arm. The float will rise or fall corresponding to the actual fuel level. When the ignition is turned on, voltage is applied to the gauge completing the gauge ground circuit through the sending unit.

Movement of the Fuel Level Sensor

When the tank is full and the float is raised, a resistance value is produced by the sending unit. When there is a variation of the current flow through the gauge, the pointer moves. As the tank empties and the float resistance in the sending unit varies, the current flow through the gauge changes and the gauge pointer moves.

Upper and lower resistance values will vary from manufacturers, models and years. Refer to the shop manual for specifications.