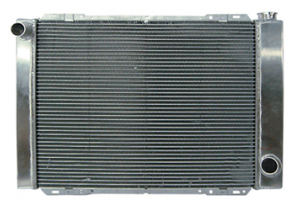

2.3 - Radiator

The radiator is the heart of the system.

It is positioned in the front of the engine in order to have access to ambient air and maximum airflow.

The cooling portion of the radiators consists of tubes and fins.

Inlet and outlet tanks enable the cooling liquid to flow in the tubes in an even distribution and reduce erosion. The radiator may also incorporate other cooling devices such as transmission and engine oil cooler.

Radiator Construction

On today's vehicles, you will find four possible radiator constructions.

- Copper / Brass

- Plastic / Copper

- Plastic / Aluminum

- All Aluminum

Copper / Brass

First, we find the copper/brass model. In this construction, the fins are made of copper and the inlet and outlet tanks are made of brass. The brass tanks are soldered to the header of the core.

Plastic / Copper

In the plastic/copper radiators, the fins are made of copper, but the inlet and outlet tanks are plastic and crimped to the core with a gasket in-between.

Plastic Aluminum

The plastic/aluminum radiators are found on 90% of today's modern vehicles. The core is all aluminum but also uses the plastic tanks crimped to the core with a gasket in-between.

All Aluminum

Last, the latest addition to the radiator family is the all-aluminum radiator which car manufacturers are using today in some new applications. This construction is commonly used in the racing industry. In addition to providing high performance heat transfer, it is reliable and lightweight.

Interchange from Copper / Brass to Plastic / Aluminum Radiator

It is very important to note that the core thickness from a copper to aluminum radiator will differ and still provide the same cooling capabilities. There are many examples of possible tube sizes based on the combination of number of rows used.