4.2 - Cooling Liquids

The cooling liquid or so-called "antifreeze" is a chemical with the ability to protect the engine from overheating and freezing. The liquid also includes additives to protect the different metals and rubbers found in the system.

Two types of liquids are used in the automotive industry. The conventional ethylene glycol liquid (usually green) provides essential protection against rust and corrosion. This conventional liquid must be replaced on a 24 month or 25,000 miles / 40,000 kilometres interval.

Starting in the mid 90's some manufacturers started using extended life liquids. Colors vary from red to blue and are formulated with organic or hybrid additives that will extend the liquid life up to 60 months or 95,000 miles / 150,000 kilometres. The liquids must be mixed with clean demineralised water at 50/50 solution. This mix will protect the engine against overheating and freezing.

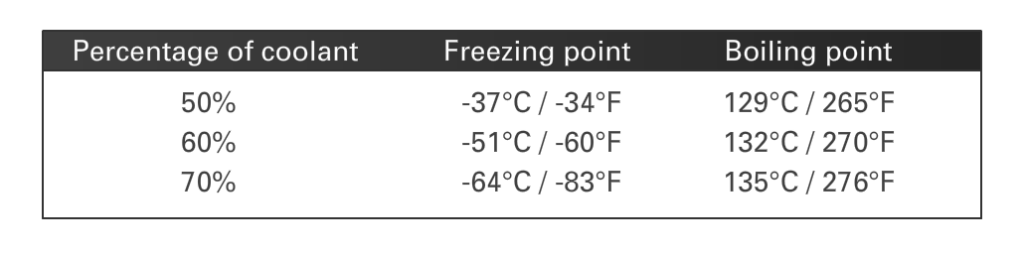

The liquids are mainly used to prevent freezing during cold weather and increase the boiling point of the liquid to prevent liquid evaporation during the warm season. Usually, the minimum and maximum protection goes from -37°C/-34°F to 128°C/265°F.

This chart shows freezing and boiling protection with the mix percentage of coolant liquid and water.

Aging antifreeze causes the depletion of additives and increases system deterioration. The freezing and boiling points of the coolant will still be good as long as it is mixed at the correct ratio. If you mix traditional antifreeze with long life antifreeze, the coolant life is shortened to that of the traditional antifreeze.

Never mix the two colors in a cooling system. The organic acid type coolants will cause precipitation of silicates in the green type and corrosion protection is greatly reduced. Some coolant liquids may also form gel type contaminants that can reduce flow and heat transfer.

System internal oxidization is often related to air in the system. Air caused by a leak, bad radiator cap or damaged overflow reservoir will always leave room for air which will with time degrade the cooling system.

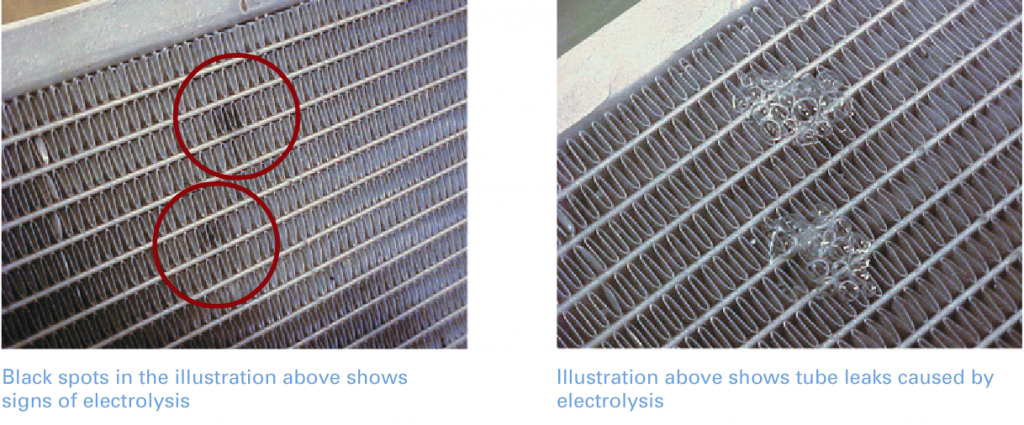

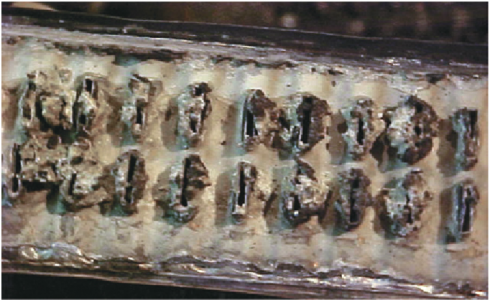

Electrolysis

Electrolysis is also part of contamination. A deteriorating cooling liquid will first change the pH balance which facilitates the formation of electrolysis. The other main cause is circulation of unwanted current through the cooling system. Stray current from bad grounds or simply added accessories that are not properly grounded will affect the radiator and heater core to the point of leakage.

Testing for Electrolysis

- Verify coolant liquid condition;

- Test the pH level of the liquid;

- Use a digital voltmeter and test as follow:

- Connect the negative lead of the multimeter to the battery negative post;

- Set the multimeter to DC volts;

- Safely remove the radiator cap or the cap on the overflow reservoir;

- Insert the tip of the positive lead of the multimeter into the coolant liquid;

- Test with the key on and turn accessories on;

- Also test while cranking the engine.

Electrolysis