3.1 - Cooling Fans

Cooling fans come in different types and models. Some are engine driven via a belt, electric motor driven or hydraulically operated through control solenoids.

Cooling fans help create an air flow through the radiator so more heat is released from the liquid. Basically, more airflow is needed when the vehicle is at low speed as air through the grill and radiator is reduced. On some models, the electric cooling fan will stop functioning when the vehicle reaches speeds above 30mph or 50km/h as airflow through the radiator is great enough to get rid of the heat.

Engine Driven Fans

Mounted on the front of the water pump, the fan is directly driven by a belt so the fan blades always follow the engine speed. These fans are usually noisy and increase fuel consumption. To help increase fuel economy, the number of fan blades and pitch are reduced.

Thermostatic Clutch Fans

The thermostatic clutch fan engages and disengages upon cooling requirements.

Filled with a silicone fluid, the clutch will be freewheeling when the engine is cold or the radiator temperature is low.

As the engine warms up heat from the radiator is sensed by clutch thermostatic bimetal strip.

The spring rotates and opens a passage to move the silicone fluid and engage the fan to the engine speed.

Electronic Cooling Fans

The electric cooling fan is operated by the vehicle's electrical power through a relay and a sensor mounted on the engine or the radiator. More common today, the on-board computer controls the fan's operation. In the example below is a two-fan motor.

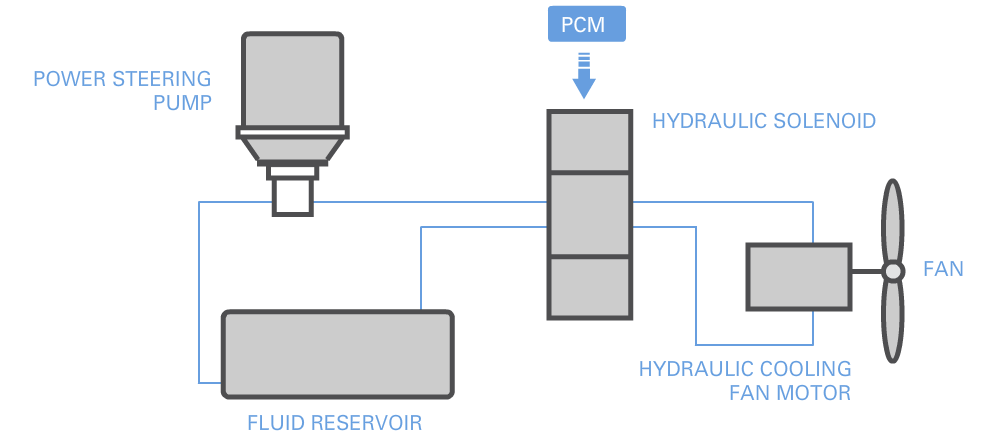

Hydraulic Cooling Fans

Hydraulic cooling fans operate like the thermostatic clutch fan with the exception of being computer-controlled by a hydraulic pump and solenoid that control the speed according to engine temperature and air conditioning input.

The most popular hydraulic fan system uses the existing power steering pump as energy and the computer controls speed through a fan speed solenoid.